Nyetimber is a producer of award-winning English sparkling wines based in the beautiful countryside of the South Downs.

They required a system to enable the tracking of the wine-making process from start to finish, ensuring that every bottle of wine could be traced through its journey from production to delivery.

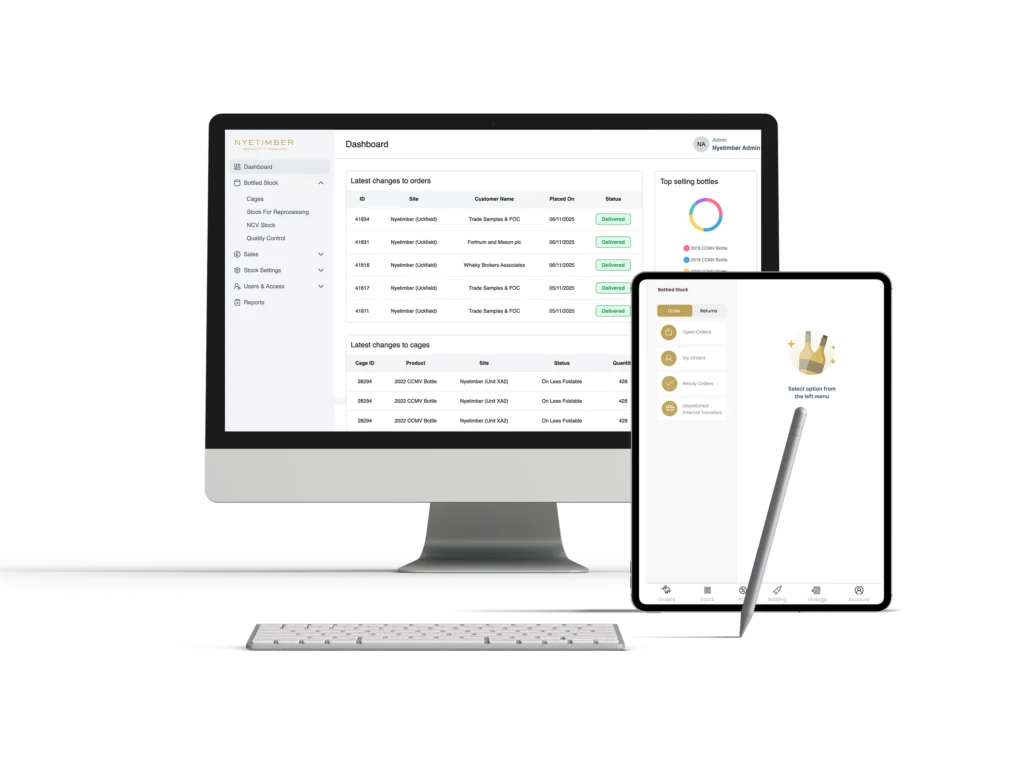

The system we developed for Nyetimber is both a process control and inventory management solution, with a web application and a mobile app to support usage on the winery floor.

The system ensures that Nyetimber can manage their stock efficiently, track the movement of wine through various stages of production, and maintain accurate financial records through integration with NetSuite.

Our process

Business Analysis

Information Gathering

We developed an in-depth understanding of the actual wine making process. This included a site visit to the wine making facilities to capture the process, with photos, interviews and videos. These were shared amongst the whole development team to provide a greater depth of understanding of our clients processes, than can be achieved with only written documentation.

Documentation

We created a detailed software requirements specification document for client approval. This allowed our client to be fully aligned with the process and deliverables.

Project Management

Our project management team scheduled weekly catch up calls with the client and created a simple project plan so that the client understood the deliverables, decision points, bottle necks and risk factors from the very start.

The client received a weekly project update report to allow them to track progress, we clearly discuss both the successes as well as any issues encountered and if these issues are likely to have an impact on the timeline. This ensures that there are no surprises.

UI and UX design

In conjunction with the client we developed wireframes and click through prototype designs for all screens both in the web and mobile applications.This was an iterative process allowing for inputs from multiple stakeholders. This collaborative approach brings together all parties and ensures that designs are not created from a singular view point.

Data and Development

Our team assessed the data requirements and data flows to deliver a data table structure that would enable future expansion of the system. Our development team worked in an agile sprint manner delivering specific aspects in each sprint and holding regular show and tell sessions with the client to keep them abreast of progress.

QA

The QA team were involved from the very first aspect of the project as they developed test cases for client approval as part of the first phase of documentation. During the project life cycle the team continuously conducts unit tests to ensure that the output from each sprint is meeting requirements. In the final stage they assist the client during user acceptance testing, especially to enable multi device and multi browser testing.

The output

Key Features of the System

- Cage Management:

- The system allows Nyetimber to create, edit, clone, and split cages, which are used to store bottles of wine at different stages of production. Each cage is tracked with a unique ID, and labels with QR codes are printed for easy scanning and tracking.

- Inventory Changes and Movement:

- The system tracks all inventory changes, including stock movements between cages, transfers between locations, and adjustments due to damages or reprocessing. Variance reasons are recorded for every change, ensuring full traceability.

- Order Management:

- The system supports the creation, approval, and processing of sales orders. Orders can be claimed, picked, dispatched, and delivered, with real-time updates to inventory levels. The system also handles internal stock transfers between Nyetimber locations.

- Mobile App Operations:

- The mobile app allows warehouse staff to claim orders, pick stock, and manage deliveries on the go. Key features include:

- Claim Orders: Staff can claim orders and prepare them for shipping.

- Order Pickup: Staff can scan QR codes to pick stock from cages.

- Ready Orders: Orders can be marked as ready for dispatch.

- Dispatched Internal Transfers: Internal stock transfers can be managed and tracked.

- The mobile app allows warehouse staff to claim orders, pick stock, and manage deliveries on the go. Key features include:

- Reporting and Dashboards:

-

- The system provides detailed reports, including:

- Cage History Report: Tracks all changes made to cages over time.

- Global Cage Report: Provides an overview of all cages and their current status.

- Dashboards offer high-level visibility of stock levels and process statuses, enabling quick decision-making.

- The system provides detailed reports, including:

Integration with NetSuite

The system integrates seamlessly with Nyetimber’s NetSuite ERP system, ensuring that financial and inventory data are always up to date. The integration includes:

- Inventory Updates: Changes in stock levels are synced between StokTrak and NetSuite.

- Order Status Changes: Sales order statuses are updated in real-time across both systems.

- Financial Reporting: Accurate financial data is maintained through two-way synchronization.

Hardware Integration

The system integrates with Bluetooth wireless printers to print labels for each cage. These labels include QR codes that can be scanned to track the movement of stock. This ensures that the system’s inventory records always match the physical location of the stock.